Feeding System For Cutlery Knife Trimming

- Huizhi Haoda

- China

- 25~45 days

- 1000 sets per month

This pneumatic feeding system could process all kinds of material for cutlery, tableware, kitchenware making, 304#, 201#, 430#, 420#, 410#.etc are available.

This item mainly used for non-magnetic stainless steel cutlery knife trimming, replace manual production, safety and efficient.

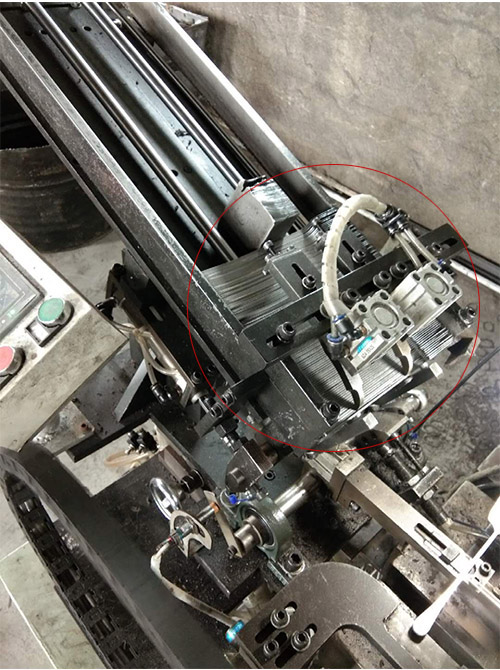

XB-203, Feeding System for Cutlery Knife Trimming

Features:

1. Pneumatic manipulator, save labor cost, one worker could operate 2~5 sets of machine at the same time.

2. High output and efficient production, with this feeding system, one machine could process 22~25 pieces of stainless steel knife per minute.

3. Improve market competitiveness, high-precision production, up to 99% succeed produce.

4. Easy operation, only need the worker to switch on/off the machine, loading and unloading the materials from feeder's inlet/outlet.

5. Safety production, no need the worker put hands into the frame of the hydraulic press or punch press machine, avoid production accident.

6. Low power consumption, 0.02kw/h.

Technical specifications:

| Thickness of the product | 1~7 | mm |

| Length of the product | 180~240 | mm |

| Process speed | 22~25 | pcs/min |

| Dimension of worktable | L480*W240 | mm |

| Dimension of material inlet/outlet | L900*W240 | mm |

| Power | 220V | 20W |

Material inlet - 900mm, could place around 200 pieces of 4mm stainless steel knife work piece:

Before process & after process:

Material outlet- 900mm, could place around 200 pieces of 4mm stainless steel knife work piece:

Do you have these troubles?

1. Received a big order, but not enough workers! Want to employ new staff, but they work slowly and with highly defective production.

2. High labor cost, low capacity.

3. The quality of the product could not reach the customer's standard, with lower market competitiveness…etc.

If your answer is YES, you could try the AUTOMATIC FEEDER! With the automatic feeder, you could realize:High efficient production, high capacity, safety production and strong market competitive ability.

Don't hesitate, just email us, you could get the Plan of Automatic Production Line for your product or factory FREELY!

Please send an inquiry with below information: 1. Photo of the sample. 2. What is material, length, weight and thickness (min & max) of the sample? 3. You capacity requirement, and your factory production situation. With this information, our engineers could help you to do the process analysis and find a good production program for you....more