Automatic Feeder For Fork Spoon Handle Embossing

- Huizhi Haoda

- China

- 25~45 days

- 100 sets per month

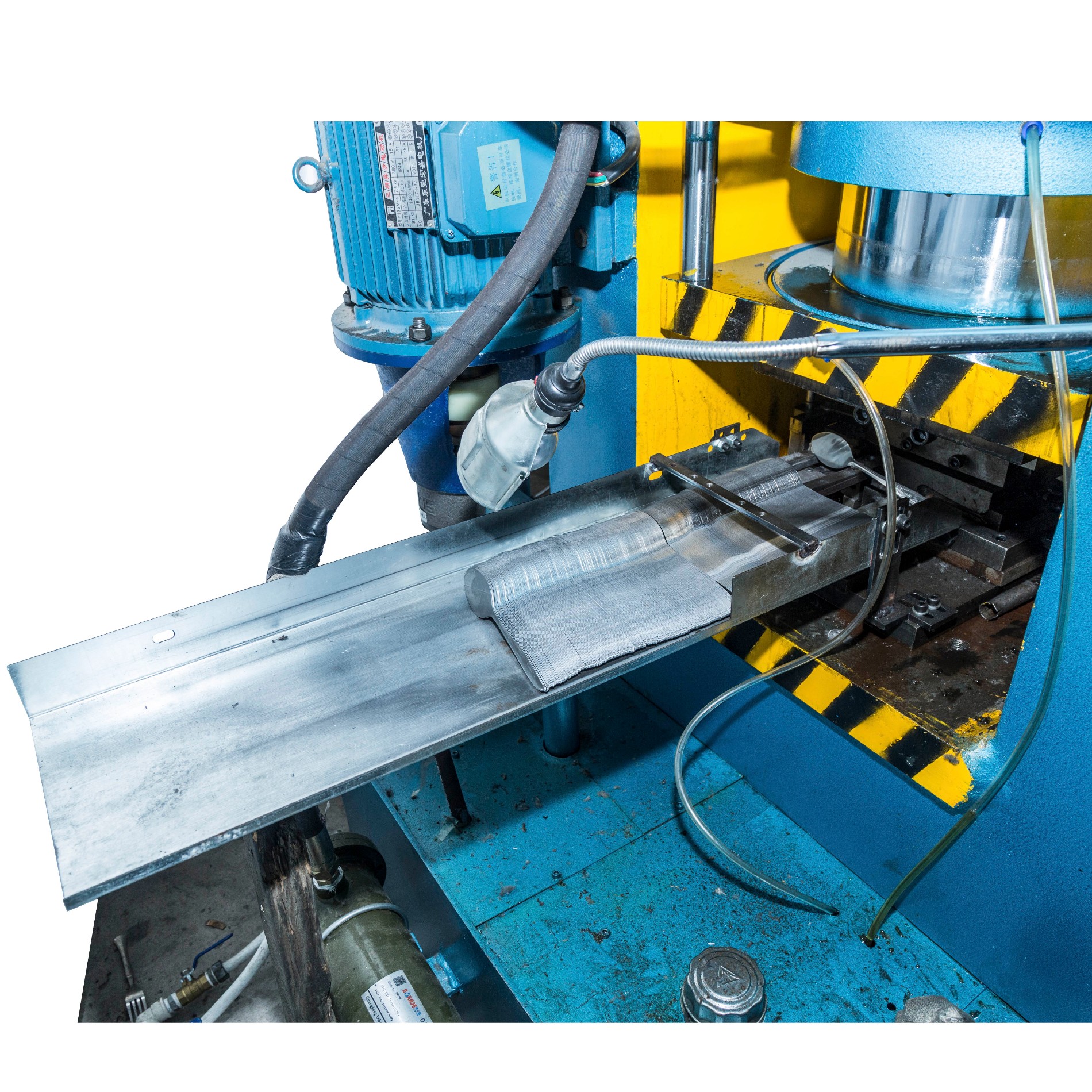

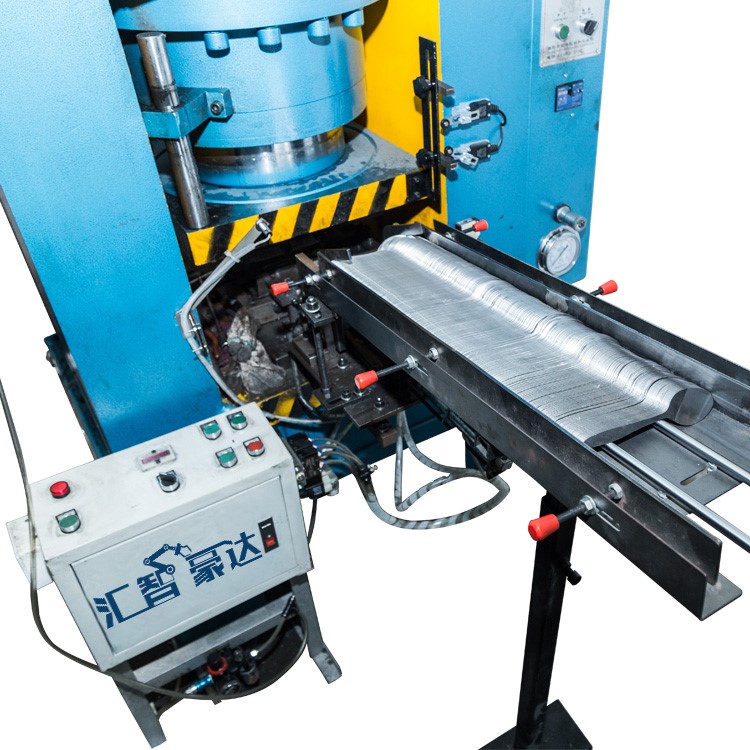

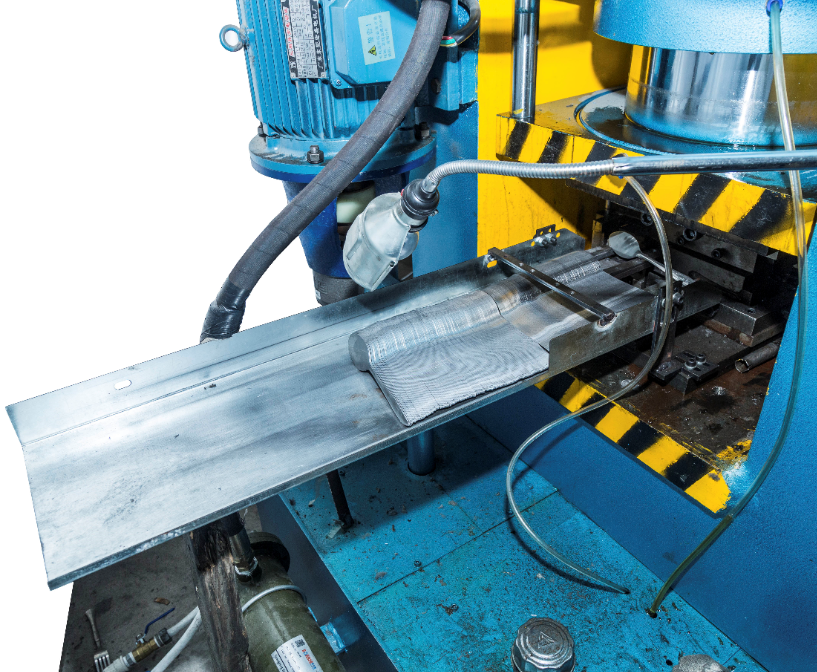

This pneumatic manipulator mainly install with hydraulic press machine, used for stainless steel spoon or fork handle embossing.

All kinds of stainless steel standard material could be process with this feeder, such as: 304#, 201#, 410#, 420#, 430#.

With this automatic feeder, you could save labor cost, improve product capacity, improve market competitiveness, decrease defective percentage and avoid production accident.

YH-201 Automatic Feeder for Fork Spoon Handle Embossing

Features:

1. High output, with this feeder, one hydraulic press machine could process 40~45 pieces of stainless steel cutlery spoon or fork per minute.

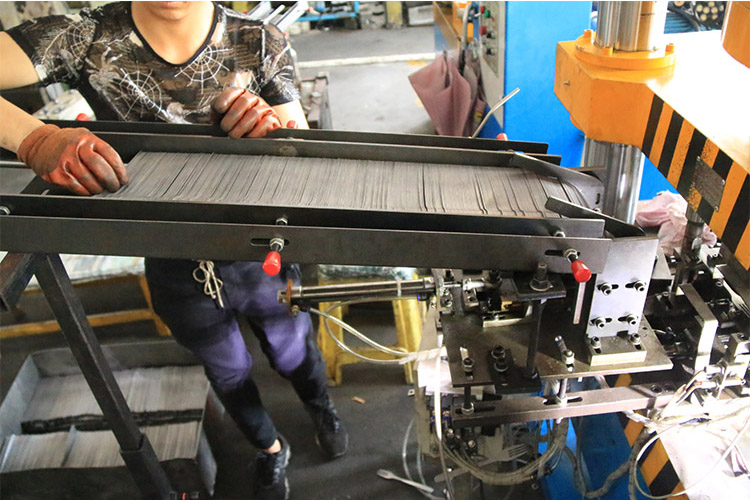

2. Save labor cost, with this feeder, one worker could operate 2~6 sets of hydraulic press machine at the same time.

3. High efficient production, differ from manual production, with long material inlet/outlet, the feeder no need stop to catch the workpiece and put down the processed workpiece, with the automatic feeder, the hydraulic press machine could work continuously.

4. Improve market competitiveness, high-precision production, up to 99% succeed produce.

5. User friendly, just a few minute training, the user could know how to operate the automatic feeder.

6. Avoid production accident, no need the operator put hands in the frame of hydraulic press machine, ensure safety production.

Technical Specifications:

| Thickness of the product | 1~7 | mm |

| Length of the product | 100~220 | mm |

| Process speed | 22~27 | pcs/min |

| Dimension of worktable | L710*W390 | mm |

| Dimension of material inlet/outlet | L900*W240 | mm |

| Power | 220V | 20W |

Images:

Inlet - Length: 900mm, could place around 400 pieces of 2mm work pieces at the same time.

Outlet - could place around 400 pieces of 2mm work pieces at the same time.

Finished products outlet:

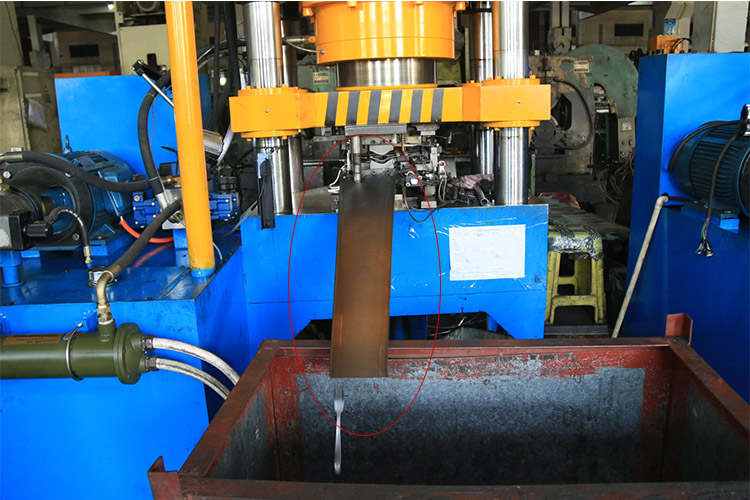

Kinds 1, directly drops into the finished product's basket.

Kinds 2, need the operator take away the finished products to the basket from the automatic feeder's outlet.

Our advantage:

1. Two independent professional R&D teams, SSHL could help you solved any technical request regards tableware & kitchenware production.

2. Engineer overseas installation, training and lifelong online counselling both for machines and products.

3. Customizable model, color and language.

4. Turnkey project or full/semi automatic production line solution are available.

5. Not lowest price but most valuable machine&service, SSHL offer your 5-STAR quality with 3-STAR price.

6. Welcome to be our dealer all over the world, and we sincerely invite your team come to Jieyang to learn the technical, installation, adjusting, setting and training.

Don't hesitate, just email us, you could get the Plan of Automatic Production Line for your product or factory FREELY!

Please send an inquiry with below information: 1. Photo of the sample. 2. What is material, length, weight and thickness (min & max) of the sample? 3. You capacity requirement, and your factory production situation. With this information, our engineers could help you to do the process analysis and find a good production program for you....more