Auto Feeding System For Cutlery Spoon Forming

- Huizhi Haoda

- China

- 25~45 days

- 1000 sets per month

This auto feeding system will work with hydraulic or punch press machine, used for stainless steel cutlery spoon forming. All kinds of stainless steel materials are available to process, such as: 201#, 304#, 410#, 420#, 430#.

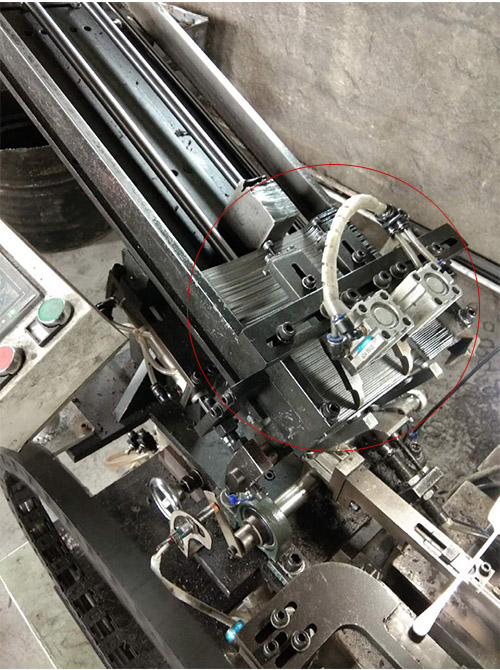

YX-201 Auto Feeding System for Cutlery Spoon Forming

Features:

1. Pneumatic manipulator, could process all kinds of material, both of magnetic and non-magnetic are available.

2. High output, with this feeding system, one press machine could process 20~25 pieces of spoon per minute.

3. High efficient production, one worker could operate 2~5 sets of machines at the same time.

4. Improve market competitiveness, high-precision production, up to 99% succeed produce.

5. Easy operation, only need the worker switch on/off the machine, loading and unloading the materials from feeder's inlet/outlet.

6. Safety production, no need the worker put hands into the framework of the hydraulic press or punch press machine, avoid production accident.

7. Low power consumption, 0.02kw per hour.

Images:

Feeder's inlet - Length: 900mm, could place around 400 pieces of 2mm workpiece.

Feeder's outlet - Length: 900mm, could place around 400 pieces of 2mm workpiece.

Before process & after process:

Technical Parameters:

| Thickness of the product | 1~7 | mm |

| Length of the product | 100~220 | mm |

| Process speed | 22~25 | pcs/min |

| Dimension of worktable | L420*W240 | mm |

| Dimension of material inlet/outlet | L900*W240 | mm |

| Power | 220V | 20W |

For more information, please inquiry us with following information:

1. Photo of the sample.

2. What's material, length, weight and thickness (min&max ) of the sample.

3. Production capacity, and your factory production situation.

With these information, our engineers could help you to do the process analysis and find a good production program for you.

Don't hesitate, just email us, you could get the Plan of Automatic Production Line for your product or factory FREELY!

Please send an inquiry with below information: 1. Photo of the sample. 2. What is material, length, weight and thickness (min & max) of the sample? 3. You capacity requirement, and your factory production situation. With this information, our engineers could help you to do the process analysis and find a good production program for you....more