Feeding System For Cutlery Spoon Making 3 In 1

- Huizhi Haoda

- China

- 25~45 days

- 1000 sets per month

This pneumatic feeding system is cooperate with hydraulic press machine, replace manual production.

Stainless steel cutlery spoon's handle embossing and double spoon cup forming could be process automatically in one hydraulic press machine with this automatic feeding system, help you save labor cost, improve production capacity and market competitiveness.

DGW-001 Feeding System for Cutlery Spoon Making 3 in 1

Features:

1. High efficient, with this automatic feeding system, one hydraulic press machine could finish three steps of the tableware/cutlery stainless steel spoon processing, they are: spoon handle embossing, spoon cup forming at twice. Blanking in, spoon out.

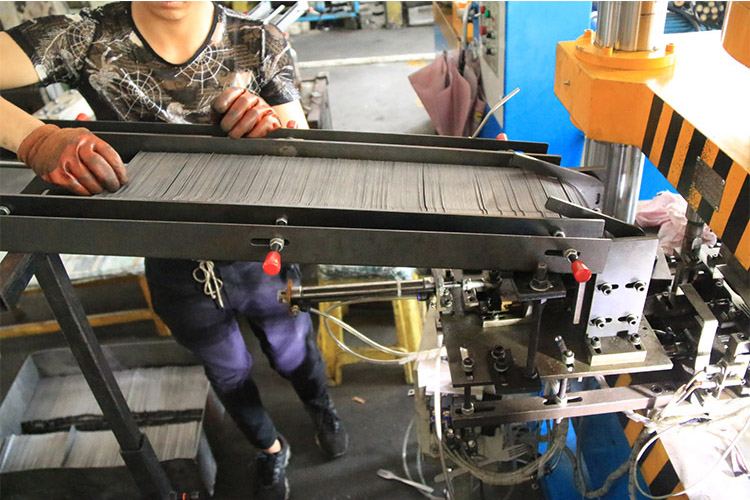

2. High output, one operator could operate 2~4 sets of machines at the same time, one machine could process 35~40 pieces of spoon per minute.

3. Easy operation and maintenance, only need the operater switch on/off the machine, loading the materials and unloading the processed product.

4. No need the operator put hands into the frame of the hydraulic press, avoid production accident.

5. Up to 99% succeed production, with this automatic, defective product could be decreased rapidly.

Description:

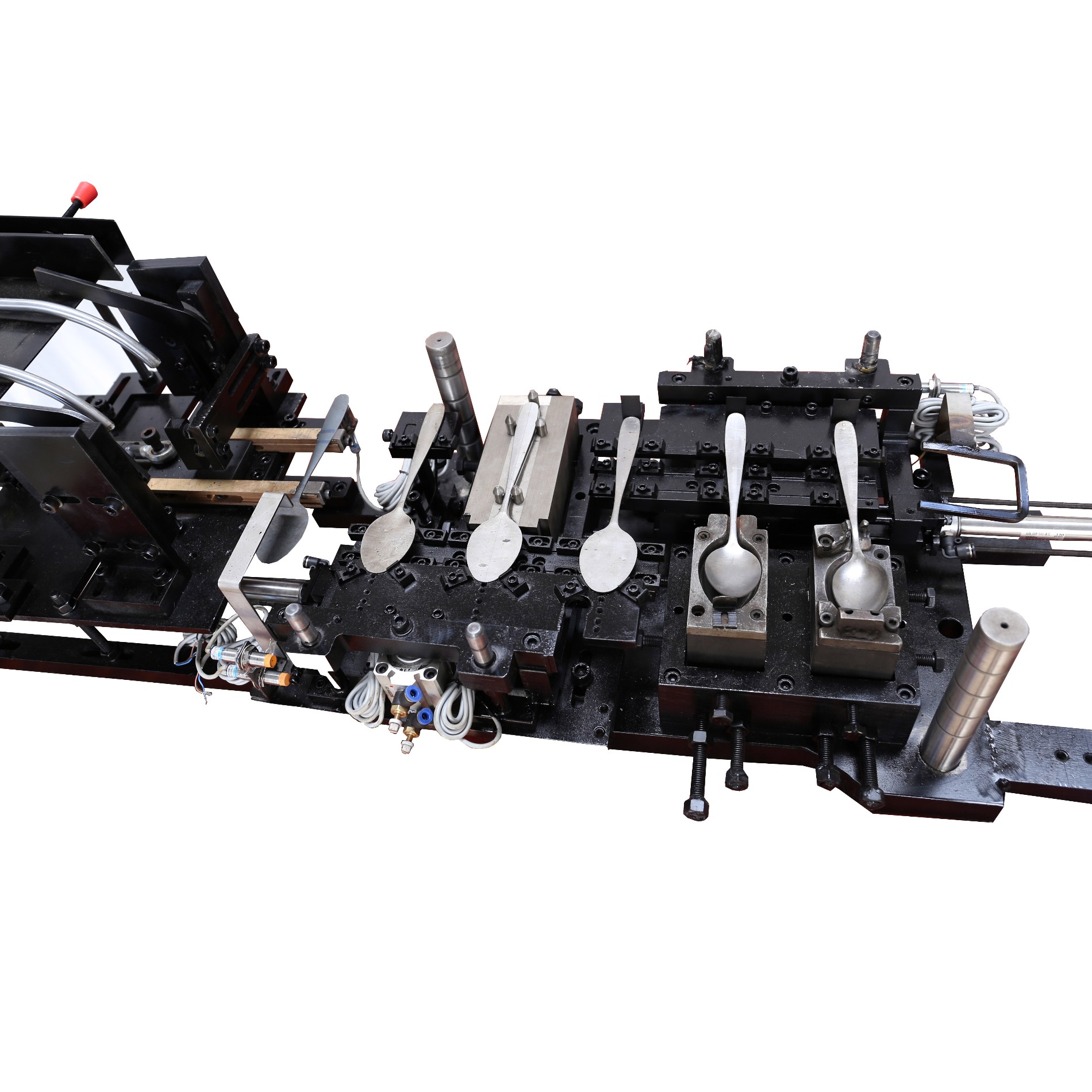

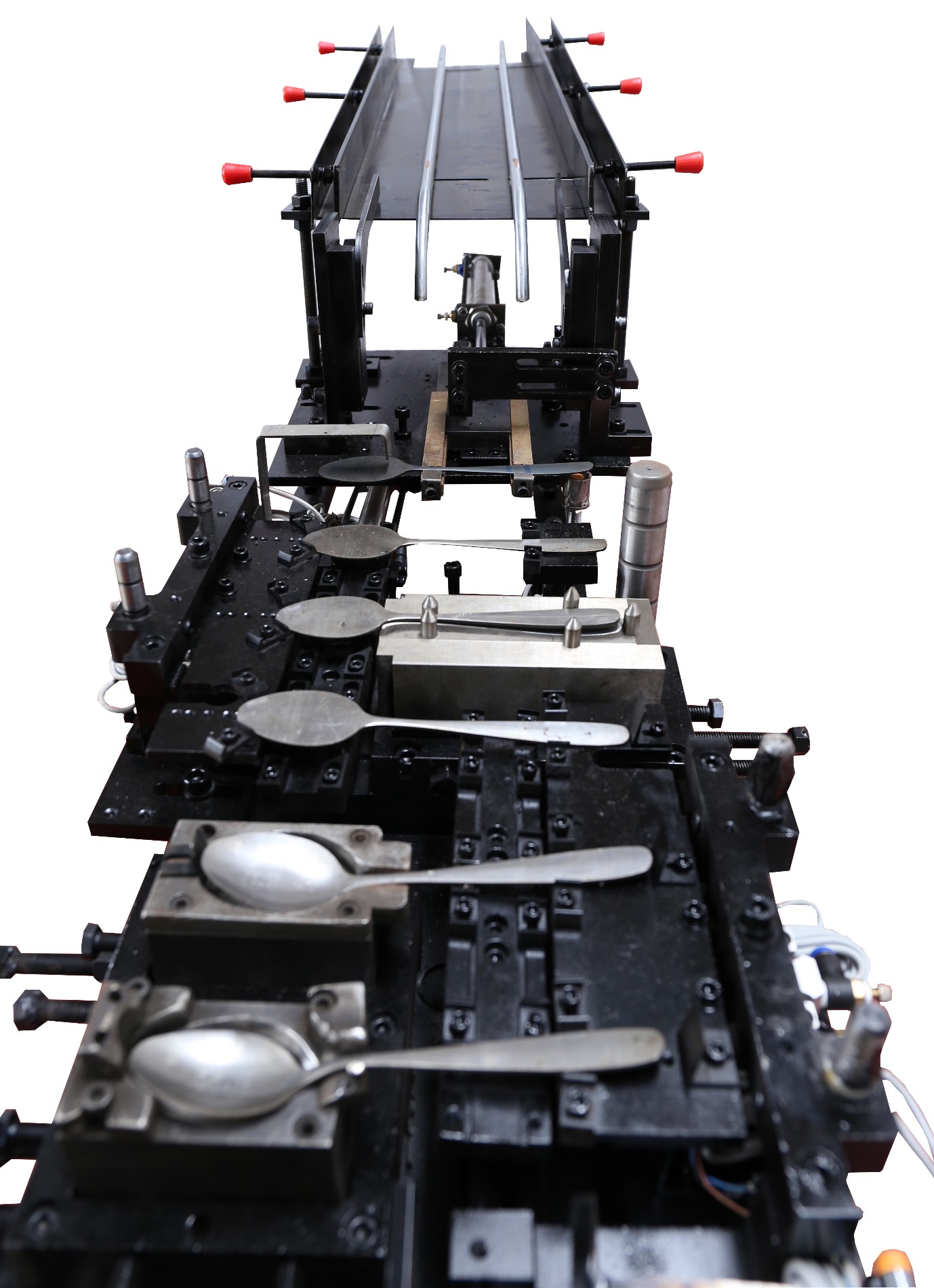

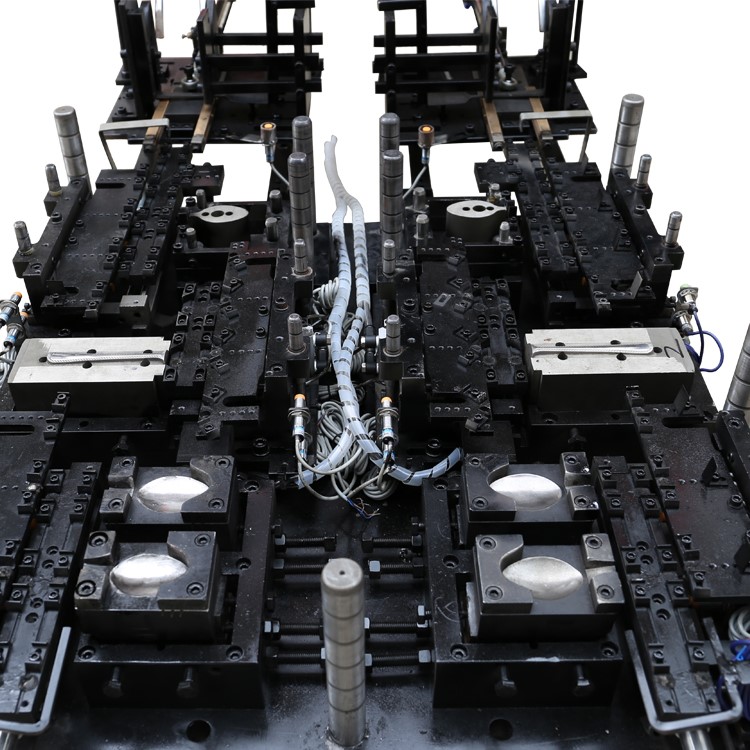

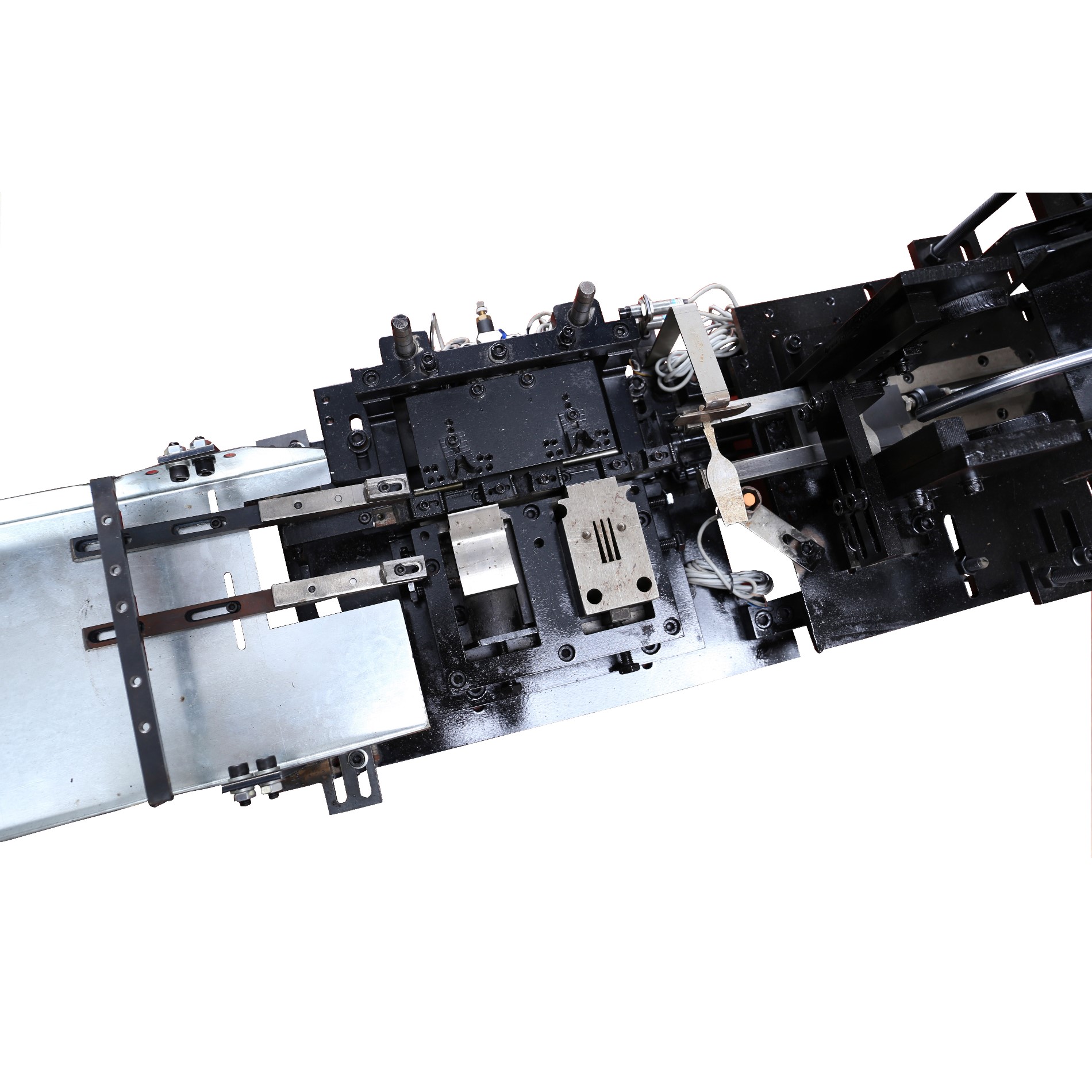

The work principle of the automatic feeding system is use the high magnetic rod to catch the stainless steel sheet from the material inlet, then the rod convey the sheet to do cutlery handle embossing, next cup forming, next final cup forming, then push the finished spoon to the feeder's outlet. Cycling work in this mode, the cutlery/tableware could be produced automatically.

This automatic feeding system not only could be used in tableware and kitchenware, but also could be used in other hardware parts production.

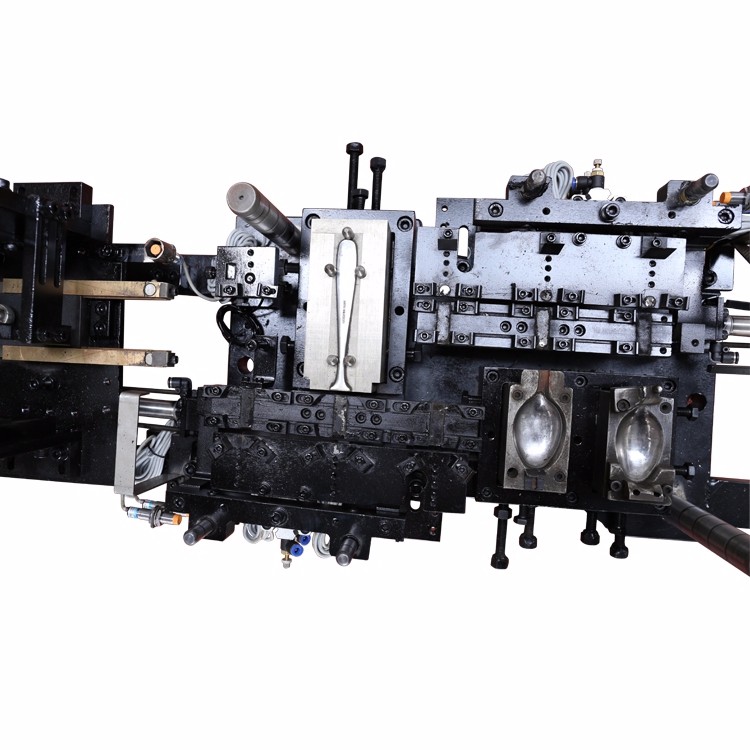

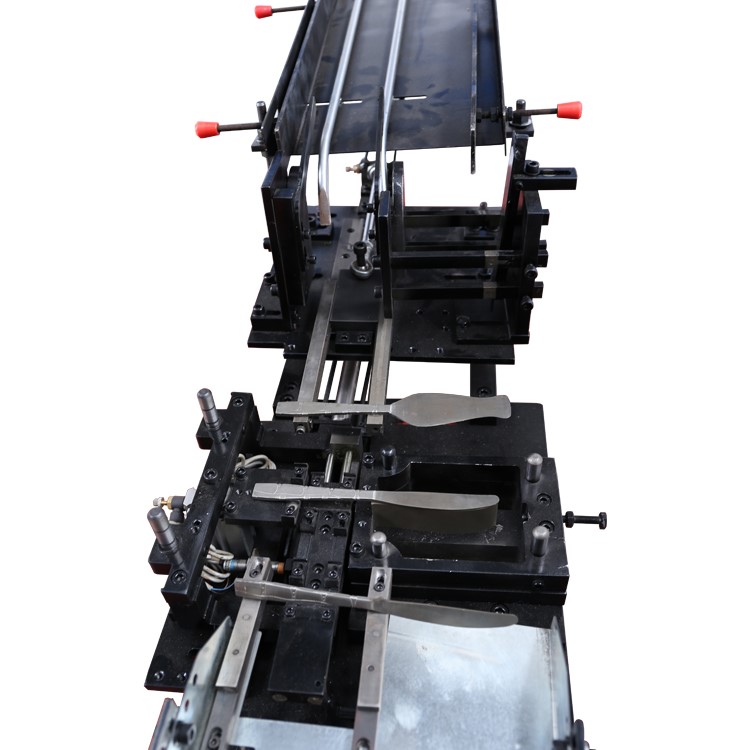

Image show:

Operation panel

Materials inlet: length - 900mm, could place around 400 pcs of work pieces at the same time.

Materials outlet: Kinds 1, length - 900mm, could place around 400 pcs of finished products at the same time.

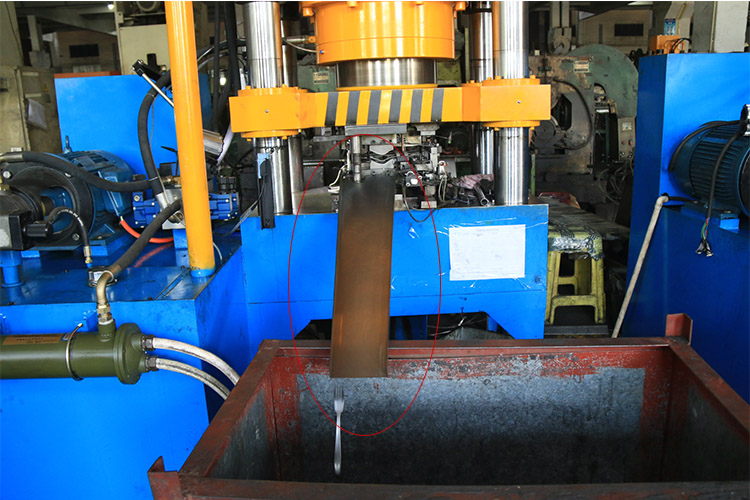

Kinds 2, processed products directly drops into the basket.

Kinds 2, processed products directly drops into the basket.

Before process & after process

Specifications:

| Thickness of the product | ≤2 | mm |

| Length of the product | 100~220 | mm |

| Process speed | 35~40 | pcs/min |

| Dimension of worktable | L560*W350 | mm |

| Dimension of material inlet/outlet | L900*W240 | mm |

| Power | 220V | 20W |

Our advantage:

1. Two independent professional R&D teams, SSHL could help you solved any technical request regards tableware & kitchenware production.

2. Engineer overseas installation, training and lifelong online counselling both for machines and products.

3. Customizable model, color and language.

4. Turnkey project or full/semi automatic production line solution are available.

5. Not lowest price but most valuable machine&service, SSHL offer your 5-STAR quality with 3-STAR price.

6. Welcome to be our dealer all over the world, and we sincerely invite your team come to Jieyang to learn the technical, installation, adjusting, setting and training.

Don't hesitate, just email us, you could get the Plan of Automatic Production Line for your product or factory FREELY!

Please send an inquiry with below information: 1. Photo of the sample. 2. What is material, length, weight and thickness (min & max) of the sample? 3. You capacity requirement, and your factory production situation. With this information, our engineers could help you to do the process analysis and find a good production program for you....more